What are the Different Types of Coating/Finishing and Why Use Them

When it comes to all the details of your print job, it can be easy to overlook coating and finishing options. Do you want your project to have a glossy appearance or more of a refined sheen? Although coating and finishing may sound the same, they are two different processes and can have different effects on the appearance of your project. Knowing your coating and finishing options can help bring out the best in your print job and help your printer fully bring your project vision to fruition.

Coating

Paper coating is a process that occurs as the paper is being manufactured. Coating is a popular choice to give paper a professional appearance and to also protect the sheets from scuffing and rubbing onto the sheets above and below during the “lift” of paper at the end of the printing process. Coating comes in gloss, matte, or satin varieties, and depending on the type of project, each type has its own benefits.

- Uncoated paper has not been treated with any coating. This type of paper has a natural, slightly rough texture that absorbs ink more readily, resulting in a softer, more muted appearance for printed images. Uncoated paper is often used for projects where a more tactile and traditional feel is desired. Uncoated paper is is easier to write on, however, the lack of coating means that colors may not appear as vibrant as they do on coated papers, and the paper may be more prone to wear and tear.

- Coated Gloss gives your project a reflective shine and is used to convey rich resolution that makes images seem to pop off of the page. Examples of projects that typically have gloss coating applied are catalogs, magazines, and children’s books. But one potential drawback of coated gloss is that fingerprints are sometimes visible on the paper due to the high shine.

- Coated Matte is applied to projects where a more diffused sheen is needed, which increases the contrast of the photos and offers a smoother presentation than an uncoated appearance. Lookbooks, graphic novels, and literary journals commonly use coated matte to achieve their subtle shine.

- Coated Satin is achieved when matte and gloss coats are mixed to create a lower gloss level than a gloss finish and a higher gloss level than a matte finish.

Finishing

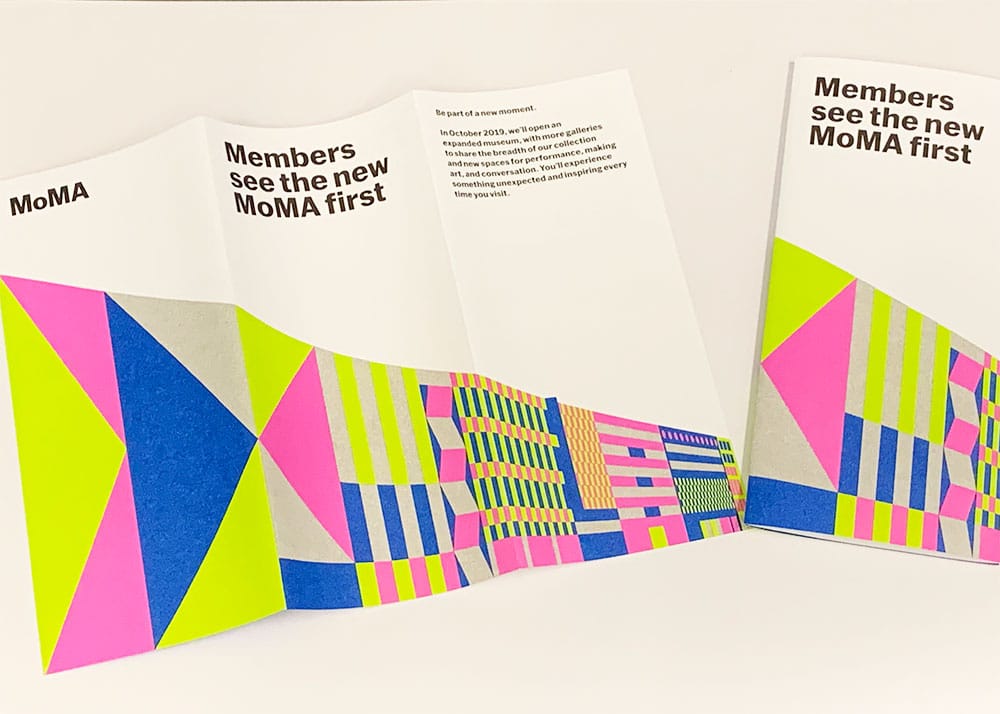

Paper finishing protects your project while adding a creative element to it, but unlike coating, finishing is applied after printing. Finishes typically have a type, such as varnish or lamination, and also a style like gloss or matte. Finishing is often used to protect paper from scratching, fingerprints, dirt and scuffing by increasing the resistance of the paper.

Varnish is a liquid finish. Vanish is applied from the printing press to seal in the printed ink on the surface. Different effects can be achieved depending on the type of varnish applied. Gloss varnish can be applied to the whole area or in specific spots with high precision. Finishing with gloss varnish can help improve image contrast and depth of colors but can affect text readability and show fingerprints due to its high reflection. Matte varnish has a non-reflective coating that can help protect the pages without affecting text readability, and satin varnish can achieve an intermediate level of shine with good scuff resistance. Comic books and magazines are projects where finishing with varnish may be appropriate.

Lamination involves applying a thin polypropylene film to the surface of the paper after printing by using a roller. Laminating your project provides it with the ultimate protection, and the sheen and texture of a lamination finish are more distinct than with varnish. Lamination comes in gloss or matte types. It’s a good rule of thumb to use lamination for perfect bound books or case bound books to protect the cover during the binding process.

UV is a coating or finish that is applied as a liquid using a roller, screen, or blanket. It is then exposed to ultraviolet light to polymerize and harden the coating. UV can be applied to both the front and back of your projects, just to one side, or it can also be applied in specific areas. UV can vary in reflectivity and thickness depending on the application, and it has many advantages in protecting the covers of magazines, catalogs, and more.

Aqueous. Also called AQ, this is a clear, fast-drying, water-based coating. It is another method used to protect the printed sheet, especially one that has heavy coverage, and can be applied during the printing process. There are several types including gloss, matte, satin, and soft touch AQ.

Speak to a Professional Printer Today

It’s important to note that not all projects require coating or finishing. Your printer will discuss all of your project options with you, including whether or not your project will benefit from the creative elements and protection of coating or finishing.

Thomas Group Printing is a fourth generation family owned and operated NYC professional printing company. Reach out to us today to discuss what finishing or coating options your next project may need to bring out the best results.