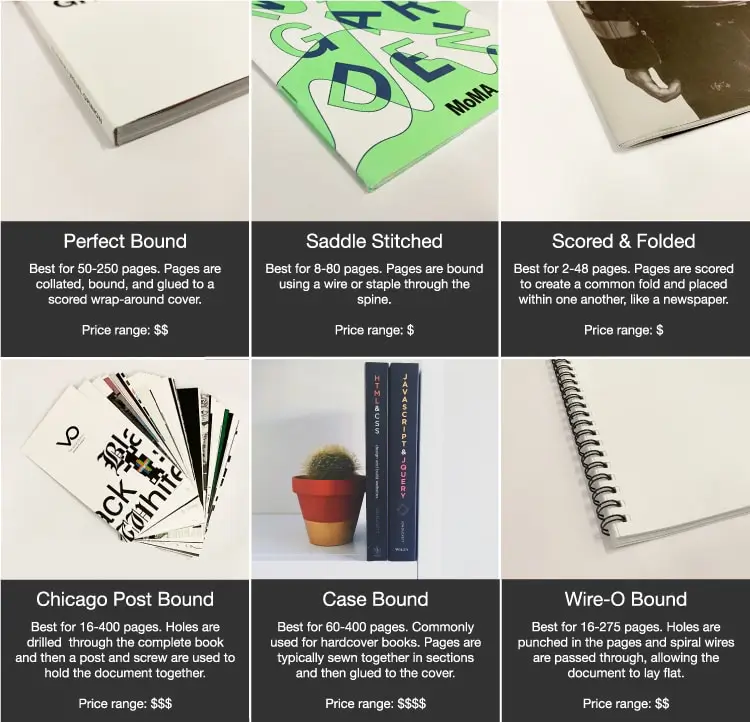

When you’re printing or producing any kind of book, booklet, magazine, catalog, zine, or other publication, at some point, the question will have to be decided: How will you bind your book or project? There are many options out there, and not all binding types are right for every product.

Thomas Group’s press team is experienced in helping our customers choose the perfect binding style for their project from our many different options. Our focus is not only on making sure you get the right binding for your book, but also that you’re satisfied in knowing you are using the best style of bookbinding that will best enhance your final product.

What Kind Of Bindings Are There? Print Binding Options

There are quite a few ways to bind a book, with each document binding type offering its own style and function. Before you can decide what kind of bookbinding you’d like for your printed project, get to know the various kinds of binding options available.

What Are The Main Types Of Document Binding?

The most common types of booklet binding are:

- Saddle Stitching: Involves folding sheets of paper together and stapling them through the fold line.

- Perfect Binding: Adheres the edges of the pages together and attaches a cover with a special glue to create a flat spine.

- Wire-O Binding: Done by inserting a wire or coil through holes punched along the edge of the pages to create a secure binding.

- Case Binding: A rigid cover with a flat spine, like a hardcover book

- Thread Sewn Binding: A binding type that involves passing a thread through each spread of the document for a decorative and functional effect

- Post Binding: A binding type that involves cutting a hole through the entire document and installing a metal post to bind the pages together, which can allow the reader to rotate the pages around the post.

Binding Types for Books and Booklets:

Below, we’ll expand on each of the binding types available for printed books, booklets, catalogs or magazines.

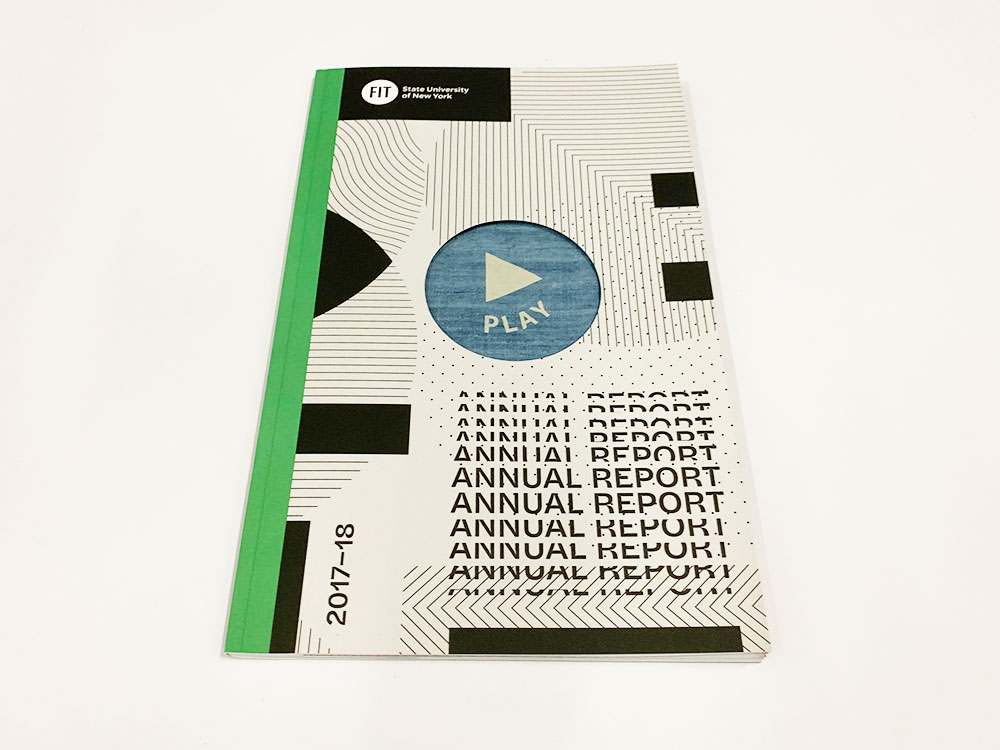

Saddle Stitch Binding

The name saddle-stitching goes back to the early days of the process when folded sheets of printed paper were draped over binding equipment resembling a saddle during binding. This name has persisted in the printing industry, encompassing any method that secures wire staples through paper sheets.

The process involves folding paper sheets and stapling them along the fold line, with two staples being the go-to options for booklets containing up to about 64 pages. While saddle stitching can handle a higher page count at lower paperweights, you run the risk of a book not laying totally flat above a 64-page count.

Today, saddle stitching still stands out as one of the most prevalent and cost-effective options for printed booklets – striking a balance between reliability and affordability. Even with just two staples, this technique creates a snug and polished product.

What’s more, saddle stitching welcomes a range of paper types and finishes, allowing you to achieve a polished look within budget constraints.

| Pros Of Saddle Stitching: | Cons Of Saddle Stitching: |

| Cost-effective | Limited page count |

| Quick turnaround | Center content may be obscured/misaligned |

| Lay-flat design | Binding visibility |

| Suitable for smaller page counts | Binding strength and longevity |

| Versatility in paper types |

Saddle-stitching’s reliability and affordability make it a staple choice for binding projects like:

- Event Programs

- Wall Calendars

- Newsletters & Annual Reports

- Pamphlets

- Direct Mailers

- Thin Magazines Like Look Books And Comic Books

- Product Or Service Catalogs

Design Considerations:

Because it relies on folded pages, saddle-stitching dictates that the total page count of the booklet must be a multiple of four. This crucial aspect should be kept in mind during the design phase to avoid blank pages.

Free book price calculator

Get a free, instant quote on your book printing project and see how your binding type affects cost. You can proceed with an order or have your quote emailed to you and held for 30 days.Your quote has been sent.

All quotes are good for 30 days. Just reply to our email to continue with your order.

If you don't receive your quote, contact production@thomasgroupprinting.com

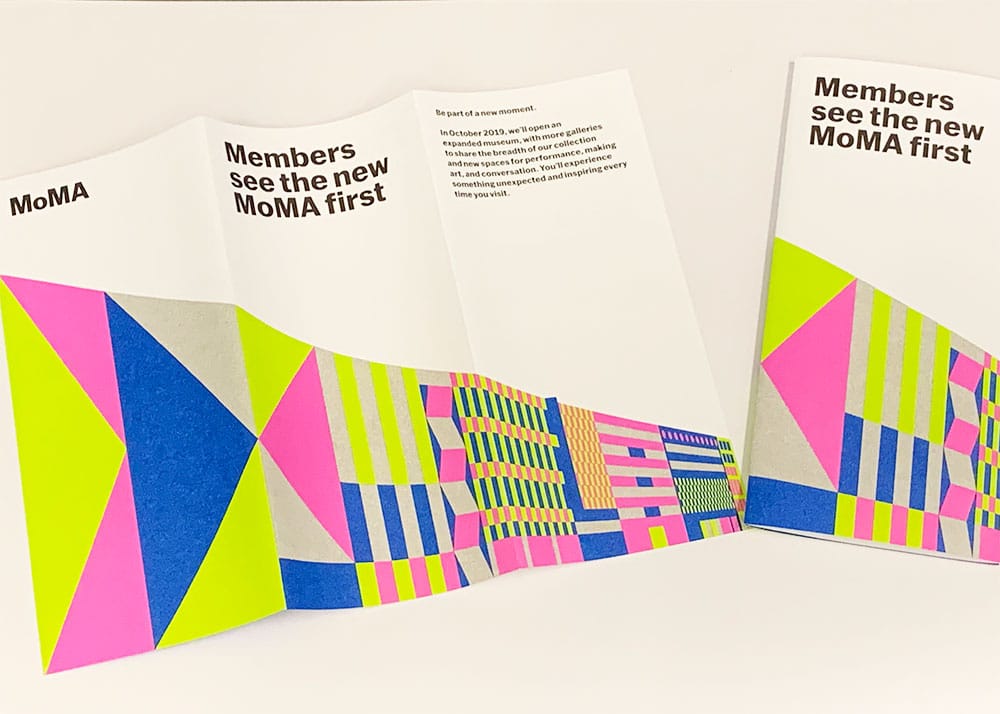

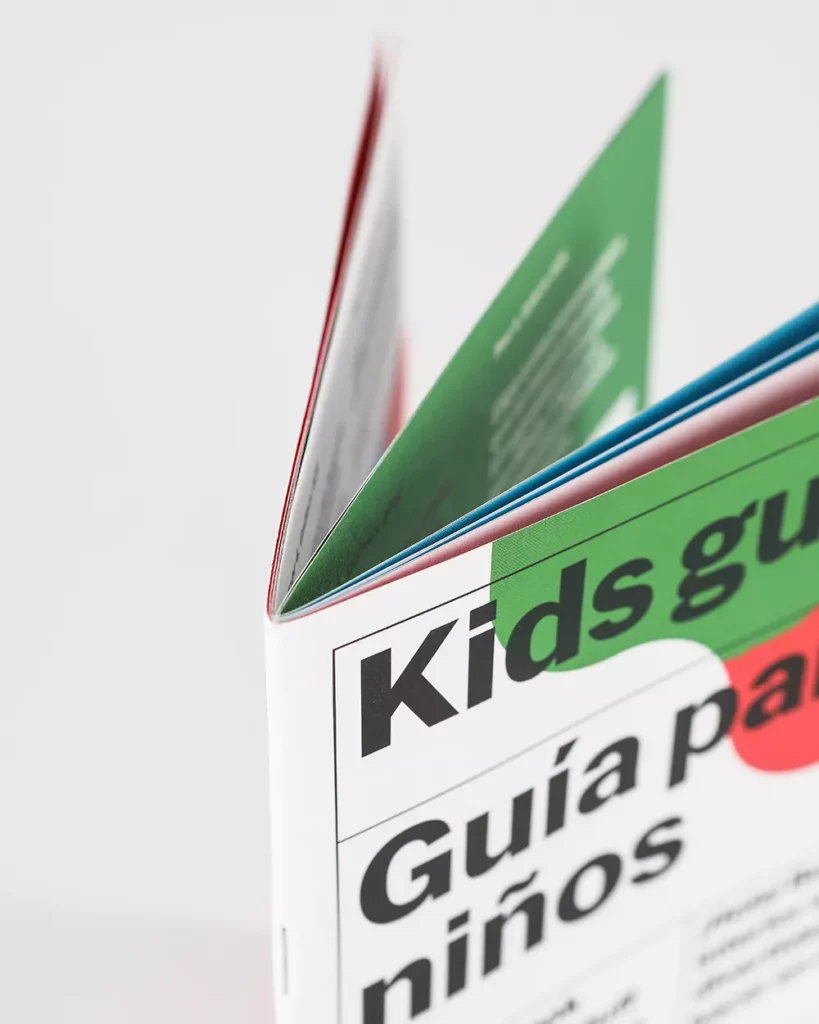

Perfect Binding

Perfect Bound books are another popular method with one big difference from other options – it uses an adhesive rather than wires or coils to hold the book together. It’s optimal for documents in the 50-250 page range which creates enough spine thickness for a strong, squared spine.

Perfect binding is done by using a strong yet pliable glue applied to the spine as collated pages are aligned and connected together. Then, they are cut to exact measurements to produce a perfect edge on all sides. Precision cutting ensures uniformity, resulting in a flawless edge on all sides.

The cover usually consists of a heavier stock of paper than the other pages. We recommend adding a clear coating for more durability and an even more visually elevated end product.

This binding method is prominently popular in bookstores for paperback and softcover books. Perfect binding is also well-loved in the corporate world because it combines cost-effective binding with a professional, clean product.

| Pros Of Perfect Binding: | Cons Of Perfect Binding: |

| Professional appearance | More expensive than saddle stitching |

| Spine printing | Longer production time |

| Lay-flat design | Spine creep |

| Suitable for larger page counts | Less eco-friendly due to glue options |

| Strong and durable spine binding |

Offering an easy-to-stack and highly professional finish, perfect binding suits a diverse array of projects:

- Novels

- Magazines

- Catalogs

- Thick Brochures

- Corporate Reports

- Manuals

- Thesis Or Dissertations

- Cookbooks

Design Considerations:

Perfect binding offers flexibility in page count, allowing for standard size booklets with any number of pages plus the allure of spine printing. However, it’s important to consider the thickness of the spine when designing your booklet for proper alignment and aesthetics.

Additionally, leave ample margin space near the spine to prevent important content from being obscured or trimmed during the binding process.

“I needed a rush perfect binding print job for a marketing proposal. Rory was quite helpful in answering questions and TGP delivered a beautifully finished full-bleed magazine at a decent price and excellent turnaround. I recommend them highly and will definitely use them again.”

– Jennifer T.

Popular Bound Products

- Book Printing13 standard sizes. 2 bind types.

- Catalog PrintingSomething else here...

- Lookbook Printing13 standard sizes. 2 bind types.

- Magazine Printing13 standard sizes. 2 bind types.

- Booklet Printing13 standard sizes. 2 bind types.

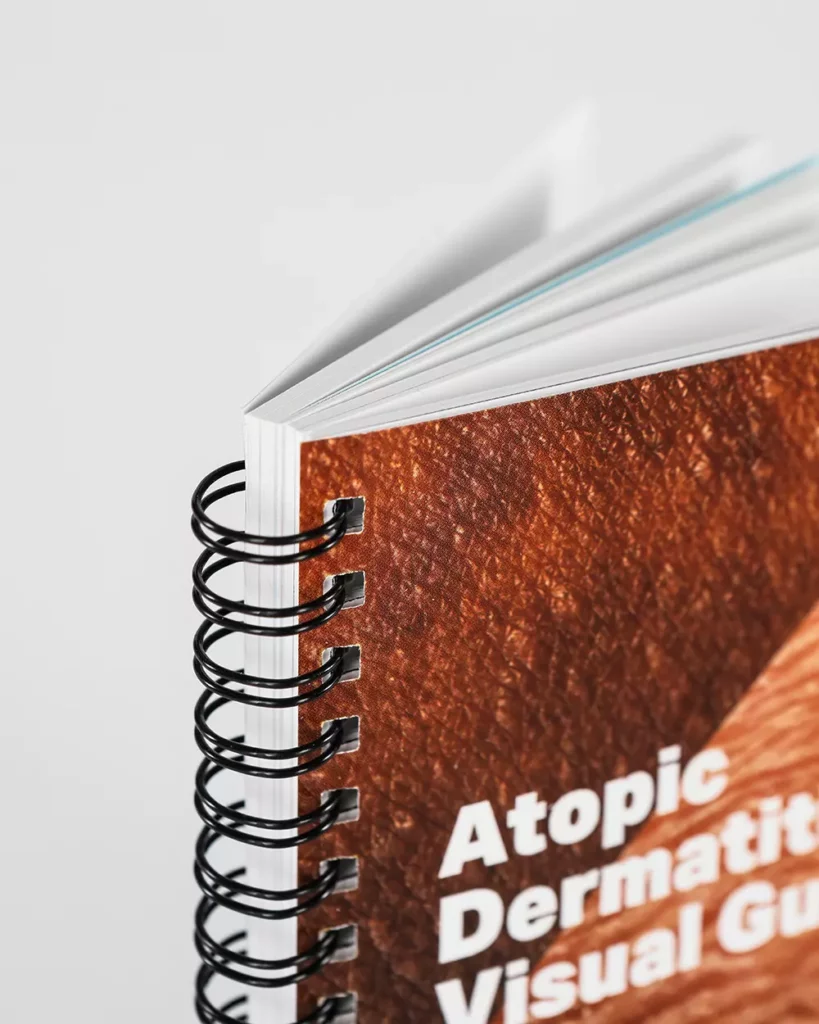

Wire-O binding

Wire-O binding stands as an economical choice for small to mid-sized printing projects, gaining popularity across various document types, including calendars and manuals.

Unlike spiral binding, Wire-O utilizes C-shaped wires threaded through document holes, forming the distinctive “O” shape upon closure. This method allows for easy page navigation and lays pages flat on surfaces for enhanced readability and usability.

Wire-O bound booklets are created by punching holes in the pages of a document and passing spiraled wires through them. This method of binding is best for documents ranging from 16-275 pages. Renowned for its durability, Wire-O offers a sturdier coil-type binding compared to plastic coils, offering superior longevity despite frequent handling.

| Pros Of Wire-O Binding: | Cons Of Wire-O Binding: |

| Compatibility with index tabs | Wire visibility |

| Versatility in page count / thickness | Limited spine width |

| 360 Degree lay-flat design | Potential for snagging |

| Easy page removal | Less eco-friendly due to metal |

| Strong and durable spine binding |

Wire-O bindings’ lay-flat abilities and strong spine make it a great choice for many printed pieces, including:

- Calendars

- Planners

- Notebooks

- Training Manuals

- Presentation Materials

- Art & Recipe Books

- Reports And Proposals

- Catalogs

- Directories & Travel Guides

Design Considerations for Wire-O Binding:

Wire-o binding offers flexibility in page count and open-flat functionality at 360 degrees. When designing your booklet, it’s important to consider the wire-o spine. The presence of the wire binding along the spine still affects the overall aesthetic and usability of the booklet.

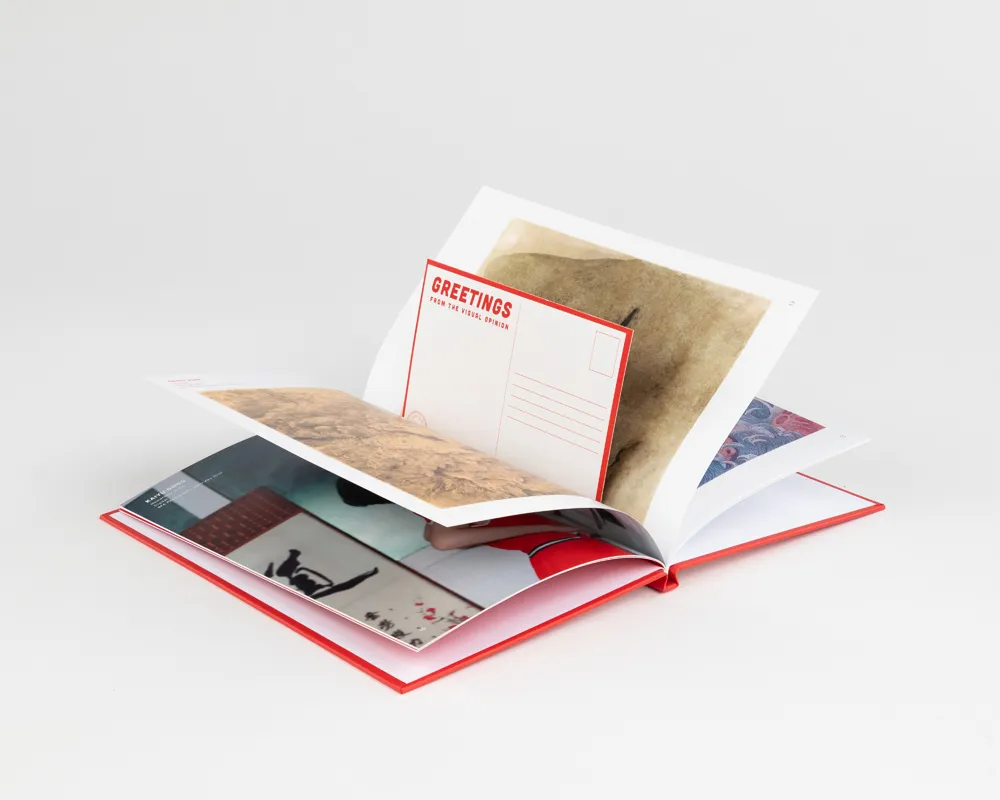

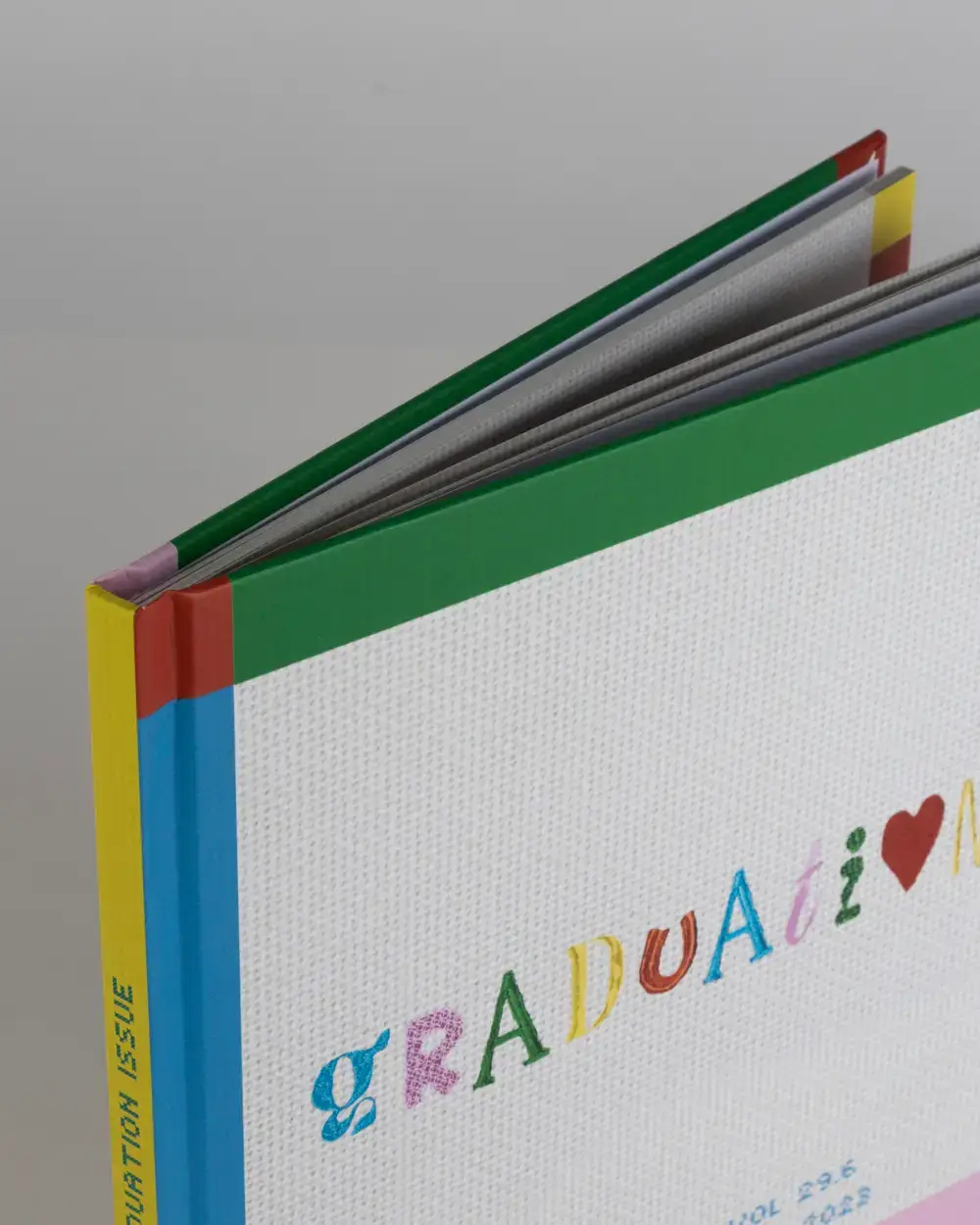

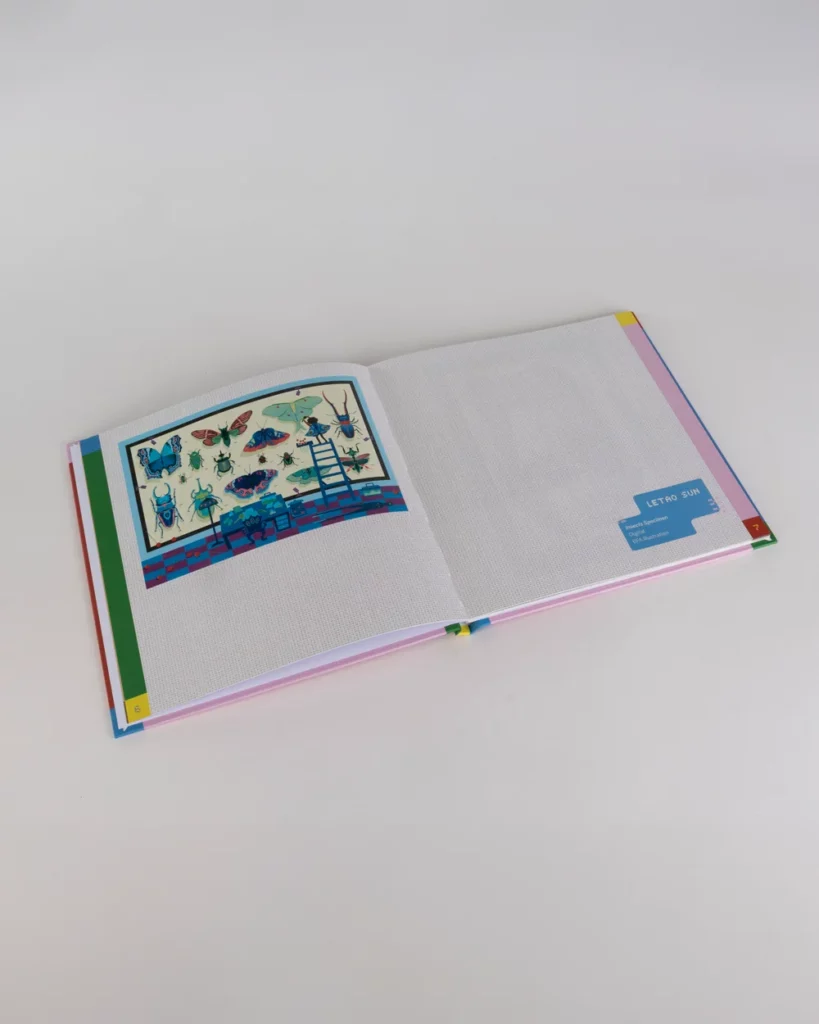

Case Binding

Case binding, also known as hardcover binding or edition binding, is a method of bookbinding commonly used for producing hardcover books. Pages are typically sewn together in sections and glued to the hardcover at the spine. This method of binding is best for documents with page counts ranging from 60-400.

It involves the assembly of a book cover, typically made from sturdy materials such as cardboard or chipboard, along with a protective covering material like cloth, leather, or paper.

When it comes to hardcover books, the typical binding that you see on nearly any version is case binding. This style of bookbinding is perfect for high-end printing projects or larger documents. And it’s a great way to make the biggest impression. It offers longevity and protection for the pages within, making it a popular choice for high-quality publications.

| Pros Of Case Binding: | Cons Of Case Binding: |

| Professional appearance | More expensive |

| Customization Options | Longer production time |

| Prestige | Size and weight |

| Lay-Flat Design | Page count limitations |

| Strong and durable | Rigid: less flexible than paperback options |

Case binding results in a durable and professional-looking hardcover book that is well-suited for several projects:

- School Books

- Hardcover Books, Such As Novels, Reference Books, Coffee Table Books, Etc

- Thesis Or Dissertations

- Annual Reports

- Limited Edition Publications

- Special Commemorative Volumes

- Legal Or Medical Reference Books

- Art Books Or Exhibition Catalogs

Case binding is the type of binding used for hardcover books.

Design Considerations:

Case binding presents an opportunity for robust and visually striking book design. However, attention to detail is crucial to ensure the final product meets both functional and aesthetic requirements.

Thread Sewn Binding

Thread-sewn binding, much like the traditional process of saddle-stitching, embodies a time-honored method of bookbinding that has persevered through the ages.

In this binding technique, folded paper sheets are meticulously sewn together along the spine using thread, resulting in a robust and enduring binding. Unlike some other binding methods, thread-sewn binding can accommodate a wide range of page counts, making it suitable for everything from moderately thin booklets to thick volumes.

Despite its simplicity, thread-sewn binding remains a preferred choice for many due to its reliability and professional appearance.

Additionally, this binding method offers versatility in terms of paper types and finishes, allowing for customization while maintaining cost-effectiveness. Whether for novels, journals, or specialty publications, thread-sewn binding provides an elegant solution for creating high-quality printed materials that stand the test of time.

| Pros Of Thread Sewn Binding: | Cons Of Thread Sewn Binding: |

| Durability | Typically more expensive |

| Lay-flat design | Longer production time |

| High quality appearance | Not suitable for very thin books |

| Structural integrity: minimizes loose pages | Requires skilled craftsmanship and specialized equipment |

| Suitable for thick books |

Overall, thread-sewn binding is versatile and well-suited for a wide range of projects that require durability, professionalism, and a high-quality finish:

- Hardcover Books

- Journals And Diaries

- Special Editions

- Thesis Or Dissertations

- Fine Art Books

- Legal And Medical Publications

- Limited Print Runs

- Luxury Branding

Design Considerations:

Thread-sewn binding offers durability and a high-quality appearance, but careful consideration is necessary to ensure optimal results.

When designing your project, pay extra attention to factors such as page layout, signature size, spine width, cover material, thread color, endpapers, and spine design. Design pages with generous margins to accommodate the sewing process while maintaining proper alignment and aesthetics.

Post Binding

In post binding, holes are drilled through the document’s pages, and metal posts are installed to screw the pages together. This method of binding is best for documents 16-400 pages in length.

This form of binding, which is also known as screw and stud binding, or sometimes Chicago post binding, requires that holes be drilled down through the completed book project. Through those holes, barrel posts are inserted and a cap screw is added to ensure the bookbinding holds well. This style is popular for industrial, art, and creative projects.

One of the key advantages of post-binding is its flexibility in accommodating varying page counts, as additional pages can be easily added or removed without damaging the binding.

Despite its simplicity, post-binding provides a professional and polished finish, making it a popular choice for both personal and professional projects. This binding method allows for customization in terms of cover materials and finishes, providing ample opportunities for creativity while maintaining cost-effectiveness.

| Pros Of Post Binding: | Cons Of Post Binding: |

| Flexibility in accommodating varying page counts | Pages may become loose over time |

| Customization options | Limited to binding along one edge |

| Easy addition or removal of pages without damaging the binding | Requires specialized equipment |

| Professional and polished finish | Not suitable for thick or heavy books |

| Versatility in binding a wide range of printed materials | May not provide as secure a binding as other methods for long-term use. |

Whether for business presentations or keepsake albums, post-binding offers a timeless solution for creating durable and visually appealing printed materials:

- Scrapbooks

- Photo Albums

- Guest Books

- Recipe Books

- Yearbooks

- Reference Guides

- Presentation Portfolios

Design Considerations:

When designing a post-bound book, designers need to pay close attention to the hole placement along the edge of the pages. Proper spacing and alignment of the holes are essential for achieving a neat and professional appearance.

Additionally, working closely with your printer in calculating the spine width accurately based on the book thickness and post diameter is crucial to ensure a secure and durable binding. By considering these factors, designers can create post-bound books that are both visually appealing and functionally effective.

Spiral Binding

A popular binding option for booklets, spiral binding is similar to Wire-O binding. Spiral binding offers a dependable solution for a variety of printing projects. It’s reliable, practical, and adaptable. Whether compiling reports or creating training manuals, spiral binding is a professional and functional binding style.

Spiral binding utilizes a continuous plastic coil threaded through punched holes along the document’s edge. This design allows pages to lay flat when opened, promoting seamless navigation and efficient workspace utilization.

What sets spiral binding apart is its versatility. From presentations to cookbooks, it’s the go-to choice for a wide range of projects, offering cost-effective solutions for endeavors of any size.

| Pros Of Spiral Binding: | Cons Of Spiral Binding: |

| Compatibility with index tabs | Spine aesthetic of visual coil |

| Versatility in page count / thickness | Limited page count |

| 360 Degree lay-flat design | Potential for coil damage |

| Easy page removal | Less eco-friendly due to plastic coil |

| Cost-effective |

Both a pro and a con: While spiral binding can accommodate index tabs, the tabs may not align perfectly with the coil, potentially affecting their usability.

Spiral bound pieces offer durable lay-flat abilities, making it a go-to option for printed pieces like:

- Report booklets

- Presentations

- Training Manuals

- Notebooks

- Calendars

- Recipe Books

- Planners and Organizers

Design Considerations:

Spiral binding provides flexibility in page count, accommodating booklets of various lengths with ease. However, it’s important to consider the thickness of the booklet and the diameter of the spiral coil when designing your document to ensure proper alignment and aesthetics.

Additionally, leave generous margin space near the edges of the pages to prevent important content from being obscured by the spiral binding and to maintain a clean and professional appearance.

Your Binding Style Impacts Your Page Count

During the printing process, different types of documents are assembled in different ways. The method of binding used can affect the number of pages that your booklet can contain. Because of this, it’s good to design with your document’s printing style in mind to get the best result for your printed piece.

Page counts for saddle stitched documents:

When a saddle stitched document is printed, a large sheet of paper will be printed front and back, then folded and stapled down the middle, effectively making a single sheet of paper into four pages. This is done to conserve paper and ensure your content is printed on every available surface.

So, when using saddle stitching, be sure your final page count is divisible by four to avoid having blank pages in your finished document.

Page counts for all other binding types:

The rules change when other types of binding are used. Since each page is bound to the document individually, they’re only printed front and back, not folded. This means that your final document page count needs to be divisible by two if choosing the following binding styles:

- Perfect Binding

- Case Binding

- Post Binding

- Wire-O Binding

- Spiral Binding

What Is The Best Book-Binding Method?

The “best” book binding method depends on your aesthetic goals, budget, and the intended use of the book. Each binding method has its own advantages and disadvantages that we’ve covered. In a nutshell:

- Perfect binding is often preferred for novels, magazines, catalogs, and other larger publications where a professional appearance is priority.

- Saddle stitching is commonly used for smaller booklets, pamphlets, and brochures, especially those with lower page counts and a need for cost-effectiveness.

- Wire-O binding is ideal for projects that require a lay-flat design, or tear-out pages like calendars, planners, and training manuals.

Ultimately, the best book-binding method will depend on the specific needs and goals of the project, as well as personal preferences and budget constraints.

What Is The Cheapest Type Of Binding?

Among common binding methods, saddle stitching is generally considered the cheapest, especially for smaller booklets, pamphlets, and brochures with lower page counts. However, the overall cost can vary depending on factors such as the size of the booklet, paper quality, and quantity of pages. You can use Thomas Group Printing’s free book price calculator to see how binding types affect your print job’s total price and can even purchase your product or hold a price that’s valid for 30 days.

Thomas Group Printing Can Help

As you can see, there are many options to choose from when it comes to having your documents bound together.

If you’re not sure what is best for your specific printing requirements, contact us! We can go over the specifics of your project and what binding options will best match your vision.

With all these choices available, we are confident we’ll be able to find the binding that best suits your expectations, the aesthetics of your project, and your budget. Get started on something awesome with one of our custom starter files.