When it comes to your branding materials, every detail counts – including paper weight. This design choice shapes how your brand is perceived from the moment someone touches your printed content. The right paper weight transforms simple printed material into a powerful communication tool, conveying a tactile experience of your messaging.

Consider the impression left by a business card that feels flimsy and easily crinkles versus a thick, substantial card that feels weighty in your hand. That’s the power of choosing the right paper weight.

Understanding various paper weights and their best uses helps you make informed decisions. By choosing the right paper weight, your first physical interaction with potential customers is memorable and aligned with your brand’s quality.

Choosing the right paper weight can be confusing due to multiple measurement methods. But don’t worry, Thomas Group Printing is here to help. We believe in providing clear information to help you make the best choices.

We’ll explain paper weight measurements in an understandable way, so the next time you need a project printed and encounter terms like “pounds” and “points,” you’ll know exactly what they mean and be able to make educated decisions that best fit your vision for your publication.

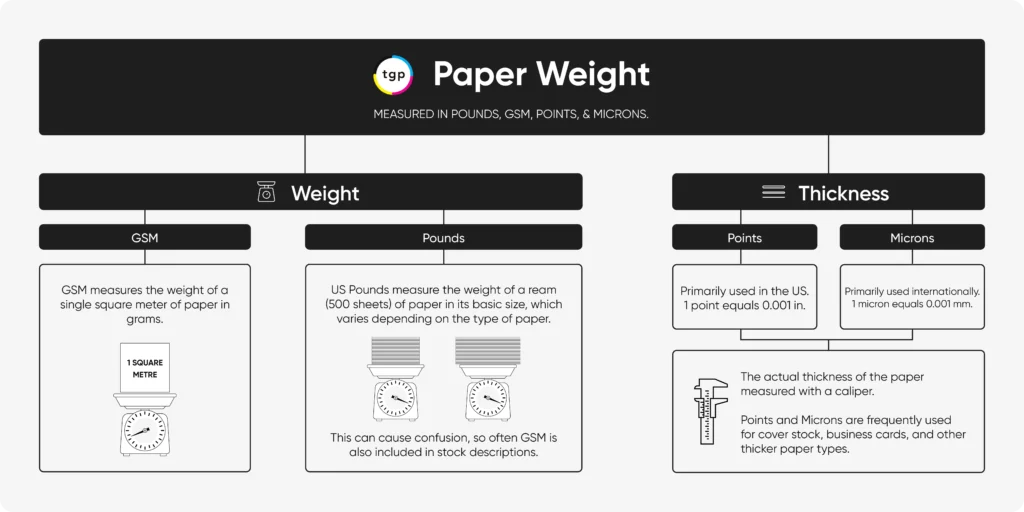

How Is Paper Weight Measured?

There are typically two ways stock is measured in the industry. The weight of paper and the thickness of paper. That’s where the terms pounds (lbs) and points (pt) come in, also sometimes seen as “#” or “lb” when referring to pounds, and a simple “pt” when referencing points (thickness).

Understanding these paper weights and their best uses can help you choose the perfect paper for your printing projects.

Understanding Paper Weight Measurements At A Glance

US Pounds and GSM measure weight, while points and microns measure thickness,

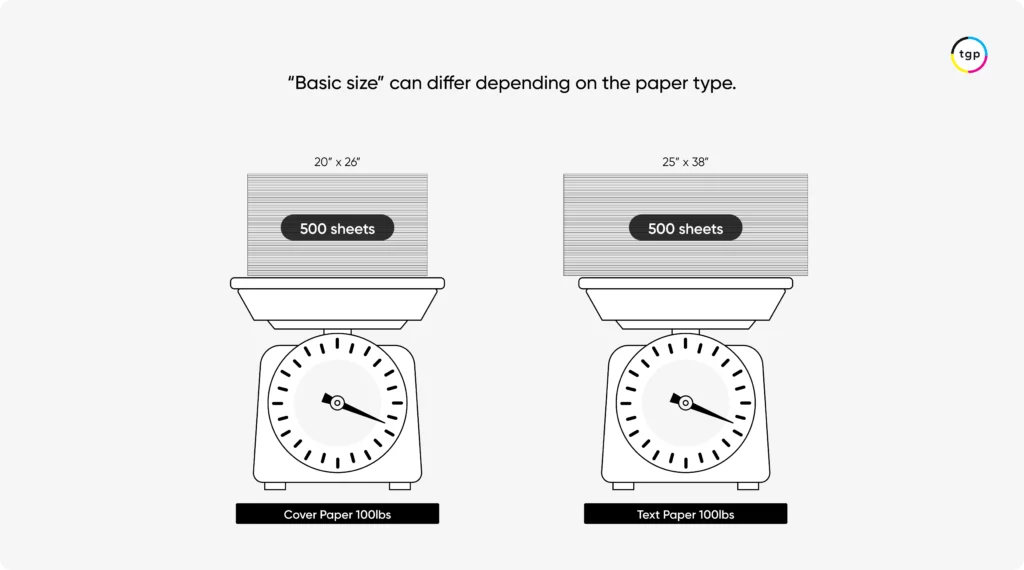

- Pounds: US Pounds measure the weight of 500 sheets of paper in its basic size. Basic size varies depending on the type of paper. This measurement is commonly used in the United States and Canada.

- Cover Vs Stock: In the US paper is also categorized as text weight and cover weight. For example, 80# Text and 80# Cover are two very different types of paper.

- GSM (grams per square meter): GSM measures the weight of a single square meter of paper in grams. This measurement is widely used internationally and is a standard metric measurement.

- Points / Microns: This is the actual thickness of the paper measured in points (0.001 inch) or microns (0.001 mm). Points and Microns are frequently used for cover stock, business cards, and other thicker paper types.

Generally, higher Pound/GSM papers have greater thickness (points/microns), but the relationship isn’t always linear due to differences in paper density and manufacturing processes.

Points Vs Pounds Paper Stock: Weight Vs Thickness

These distinctions help printers and designers choose the appropriate paper type for different components of printed materials, for both durability and the desired aesthetic.

Pound: Weight Of Paper

This measurement is typically used for the pages of a book, brochures, or general printing paper. When it comes to pounds, the term is exactly what you likely guessed: Pounds refers to how much paper weighs.

Typically a thicker paper stock equates to a higher weight – although not always.

These weights can be between 20 to 140 pounds, depending on the type of material the paper is made from. A nice bond paper (office printer paper) has weights between 20 and 80, while heavier card stock paper weight ranges between 50 and 140 pounds.

Paper weight doesn’t refer to the individual sheets of cut paper themselves.

Instead, it is determined by how much a ream of uncut paper weighs. Typically 500 sheets of paper make up a ream. That paper is weighed before being cut down to smaller sizes and is what’s used when identifying and categorizing the product.

The variation in basic sizes makes the pound measurement complex and often difficult to compare directly across paper types.

Cover Paper: If a cover stock has a basic size of 20″ x 26″ and 500 sheets at this size weigh 100 pounds, the paper is classified as 100 lb cover paper.

Text Paper: If a text stock has a basic size of 25″ x 38″ and 500 sheets at this size weigh 100 pounds, the paper is classified as 100 lb text paper. However, 100# text and 100# cover will not feel the same in hand.

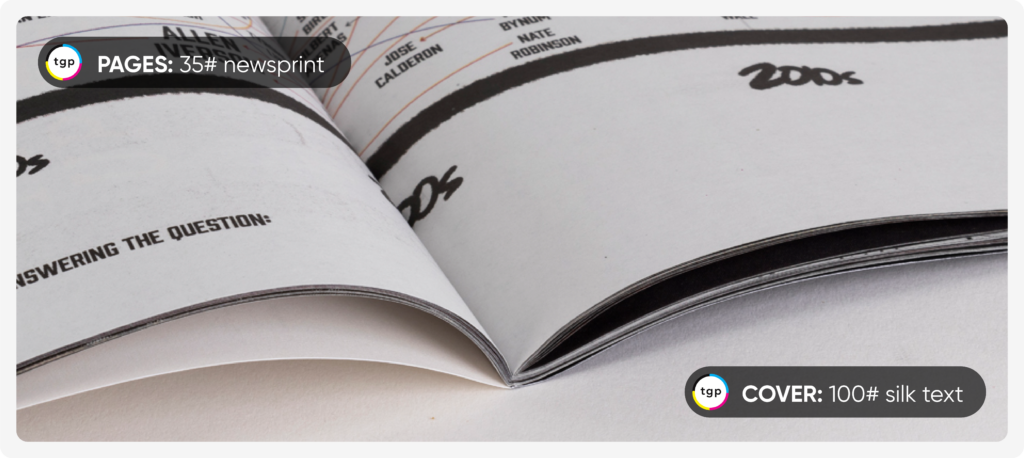

However, 80# newsprint and 80# cover will not feel the same in hand. The cover stock will be firm and may be glossy while the newsprint will be thin and uncoated.

Text vs. Cover Paper Weight

If that’s not complex enough, in the U.S., paper weights are classified by basis weight, including bond, book, cover, index, tag, and text paper. Each type has specific weights and is suited for particular uses.

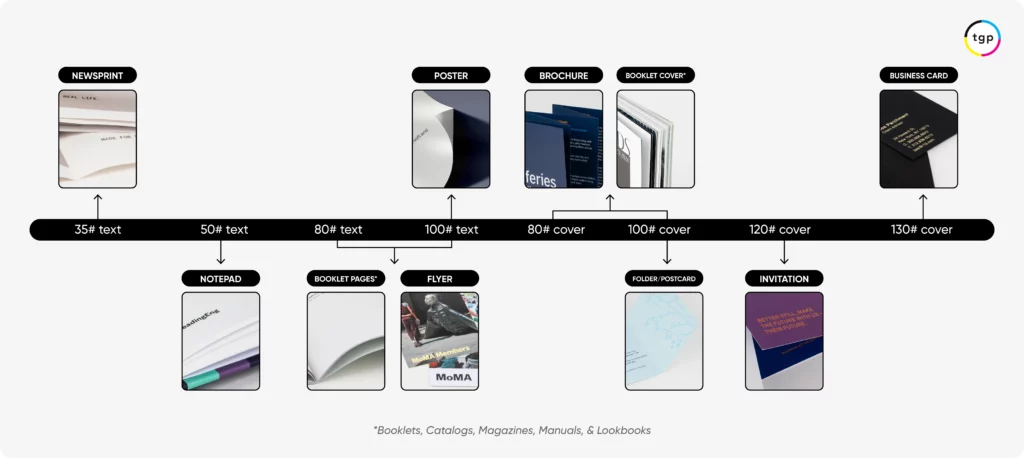

Paper for commercial printing will likely be categorized as text weight and cover weight. When choosing paper for your printed materials, knowing the difference between text weight and cover weight is key. 100# text and 100# cover are two very different paper options.

Text Weight:

Text weight paper is thinner and flexible, perfect for the inside pages of brochures, newsletters, and flyers. It typically ranges from 30# to 100#, offering a good balance between durability and ease of handling.

Common Text Paper Weights:

- 35-pound text: This is the paper you’ll find in newsprint pieces like workbooks, magazines, and newspapers. It’s one of the lightest stocks available.

- 60-pound text: This paper is often used for inside pages for paperback books.

- 80-pound text: The most common weight for magazines and smaller catalogs, along with booklets and sometimes the text pages of hardcover books.

- 100-pound text: This versatile weight can be used in booklets as either text or cover. It’s good for the text pages in children’s books, coffee table or art books, or for comic book covers and brochures. It’s light enough for saddle-stitching and heavy enough to provide a cover quality. It’s also often used for posters as a durable stock.

Cover Weight:

Cover weight paper, on the other hand, is thicker and sturdier, ideal for business cards, postcards, and brochure covers. It usually ranges from 60# to 120# or more, providing a substantial, premium feel.

Common Cover Paper Weights:

- 80# cover: One of the lightest cover stocks available, good for brochures, buckslips, and booklet covers. Works well for smaller perfect-bound projects like handbooks.

- 100# cover: A common stock for booklet covers, brochures, folders, buckslips, postcards, and invitations.

- 130# cover: A heavy cover stock, typical for business cards and suited to projects that will be handled a lot or require a heavier cover, like oversize perfect-bound products.

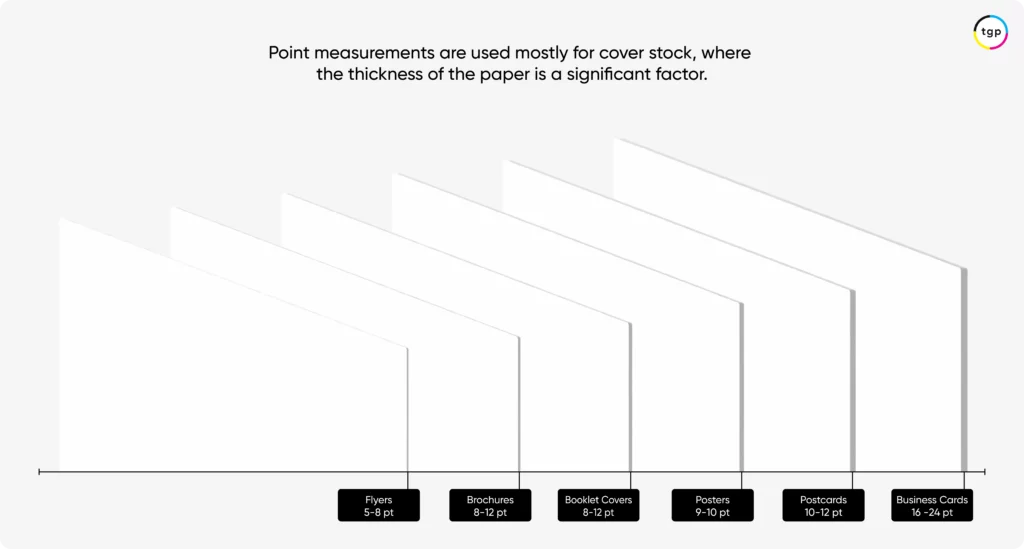

Points: Thickness Of Paper

Points measure the thickness of paper rather than the weight, which don’t always correspond directly to each other. This measurement is commonly used for cover stock, which is thicker and more rigid than text or bond paper.

Using points to determine paper thickness is a bit more scientific, even using instruments to measure the thickness down to each 1/1000th of an inch.

The higher the point value, the thicker the paper. So a 10-point paper is 10/1000ths of an inch in thickness. While 16-point paper measures in at 16/1000ths of an inch. While that doesn’t seem significant when comparing numbers to numbers, it is actually quite noticeable in the final printed product.

GSM Vs Microns: Weight Vs Thickness

In the US and Canada, paper weight is most often discussed in Pounds (#) and Points (pt) but internationally, GSM and Microns are used.

Paper Weight: GSM

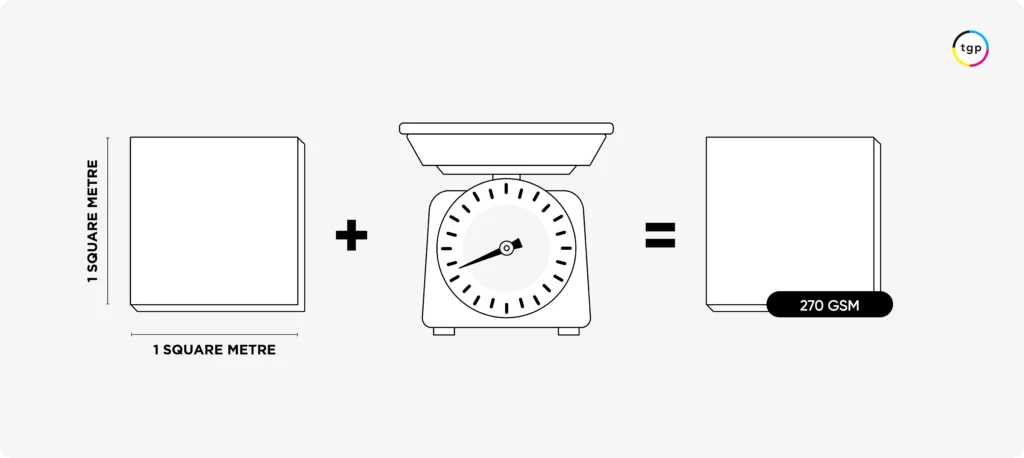

You may come across some other paper weights that are less common than points and pounds. One that is becoming more frequently used in the industry is the GSM.

GSM stands for grams per square meter of paper. Defining the GSM – the weight of paper in grams – is a more straightforward measurement as the paper is measured in the same dimensions: a square meter.

This measurement uses the metric system, which is more widely used internationally.

- Low GSM (35-55 GSM): These papers are very light and thin, often used for newspapers where a lower cost and ease of folding are priorities.

- Medium GSM (70-120 GSM): This range is suitable for general-purpose printing such as magazines and brochures, offering a balance between durability and flexibility.

- High GSM (130-250 GSM): Thicker and more durable, these papers are used for covers, postcards, and high-quality brochures, where sturdiness and a premium feel are desired.

- Very High GSM (300-350 GSM): Extremely thick and robust, these papers are ideal for business cards and packaging, providing a strong, high-quality finish.

By understanding the GSM and thickness relationship, you can better choose the best paper for your specific printing needs.

Paper Thickness: Microns

Microns measure the thickness of paper, providing a precise metric measurement. It’s often used internationally. One micron equals one-thousandth of a millimeter (0.001 mm). A higher micron value directly equates to thicker paper. For example, 200 microns equals 0.2 millimeters, while 500 microns equals 0.5 millimeters.

Microns are commonly used for specialty papers in packaging, scientific documentation, and various industrial applications where exact thickness measurements are critical.

Paper Weight Chart with Conversions

This Paper Weight Chart provides a comprehensive comparison of common paper weights in pounds, GSM, points, and typical uses in commercial printing.

Paper Type | Pounds (lb) | GSM | Points (pt) | Microns |

Standard Sticky Note | 20# bond | 75-80 | 4-5 | 100-125 |

Premium Printer Paper | 24# bond | 90 | 5-6 | 125-150 |

Newsprint | 35# text | 50-55 | 2-3 | 50-75 |

Booklet Pages | 80# or 100# text | 118-148 | 5-8 | 120-180 |

Flyer | 80# or 100# text | 118-148 | 5-8 | 120-180 |

Poster | 100# text | 148 | 9-10 | 170-180 |

Brochure | 80# or 100# cover | 216-270 | 8-12 | 200-250 |

Booklet Cover | 80# or 100# cover | 216-270 | 8-12 | 200-250 |

Folder/Postcard | 100# cover | 270 | 10-12 | 250-300 |

Invitation | 100-120# cover | 270-325 | 10-14 | 250-350 |

Business Card | 130# cover | 352-400 | 16 | 400 |

Paper Thickness Doesn’t Always Equal Paper Weight

More thickness does not always translate directly into more weight. While there is a general correlation between the two, they are distinct measurements and can vary based on several factors, including the type of paper, its composition, and the paper quality.

Factors influencing the relationship between thickness and weight include:

- Density and Composition: Different paper grades can have different densities. For example, a high-quality, dense paper may weigh more without being significantly thicker. Conversely, a low-density paper might be thicker but weigh less.

- Material: The type of fibers and fillers used in the paper can affect both weight and thickness independently.

- Coating and Finishing: Coated stock (like gloss or matte finishes) can be heavier due to the additional material, even if the base paper thickness is the same.

In commercial printing, choosing the right paper involves considering both the weight and the thickness to achieve the feel, durability, and print quality you want for the specific project.

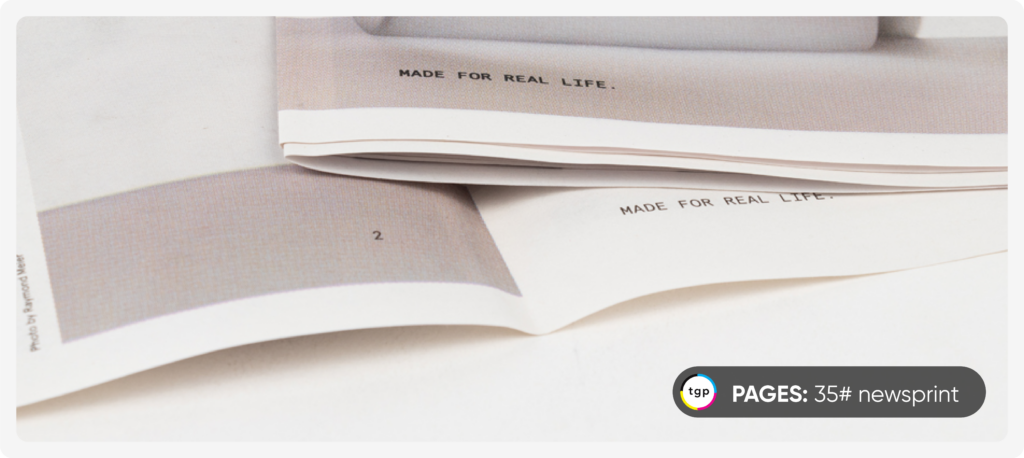

This Pureology piece (left) is printed on 35# Newsprint and the Hiroshi piece (right) is printed on 80# uncoated text. You can see the difference in the thickness and flexibility of the two different paper weights.

Basics of Paper Grades

While we explain the relationship between paper weight and thickness, it can be helpful to understand paper grades too. Paper grade refers to the quality and type of paper based on aspects like fiber content, surface finish, and intended use. Here are common paper grades:

- Premium Grade: High-quality paper with excellent smoothness, brightness, and often a higher GSM. Made from superior materials and has a refined finish.

- Standard Grade: Good quality paper that balances cost and performance. It has decent brightness and smoothness and is suitable for everyday use.

- Recycled Grade: Made from recycled materials, often mixed with some virgin fibers to maintain quality. Can range from basic to high-quality finishes.

Basics of Paper Coating

Paper coating plays a role in paper weight. Paper coating falls into two primary categories: coated and uncoated. In each category, there are differences between options and cover stocks and text.

Coated stocks: These include gloss-coated and silk coated.

- Gloss Coated Paper provides a high-shine, vibrant finish, perfect for materials that require bright colors and sharp images but can be prone to glare and fingerprints.

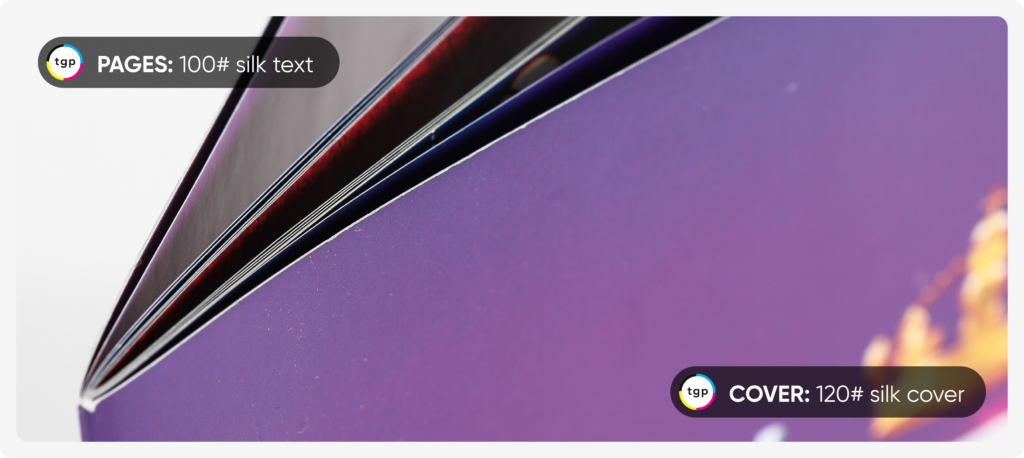

- Silk Coated Paper offers a smooth, elegant finish with reduced glare, making it ideal for readable, high-quality prints while being less vibrant than gloss.

The most common weights for gloss and silk coated covers are from 80 to 130 pounds, and for text range from 80 to 100 pounds. Uses might include pocket folders, packaging and display, or postcards.

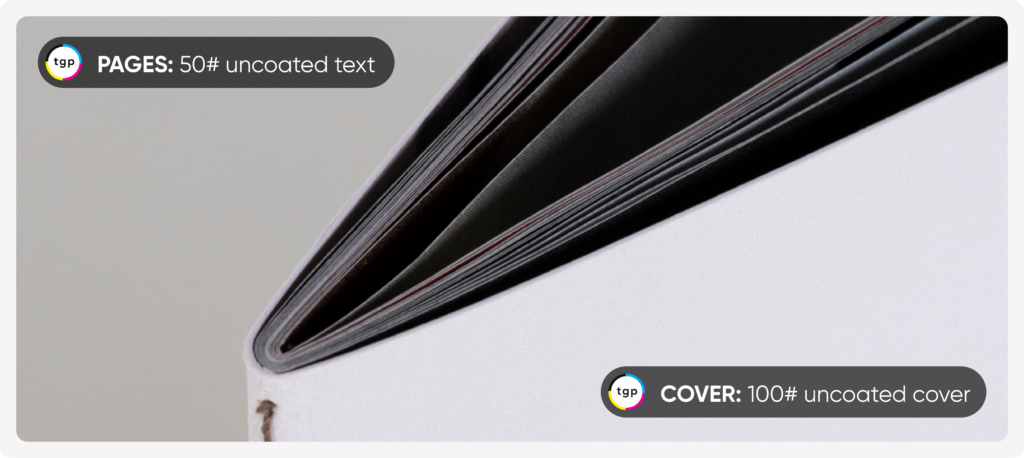

Uncoated stocks: A wide range of uncoated papers span from heavy and opaque to light and commodity-grade. Finishes might include laid finish, linen, or felted.

Weights range from 65 to 130 pounds for covers, and 40 to 100 pounds for texts. Uses include booklets, flyers, memo pads, books, brochures, and invitations.

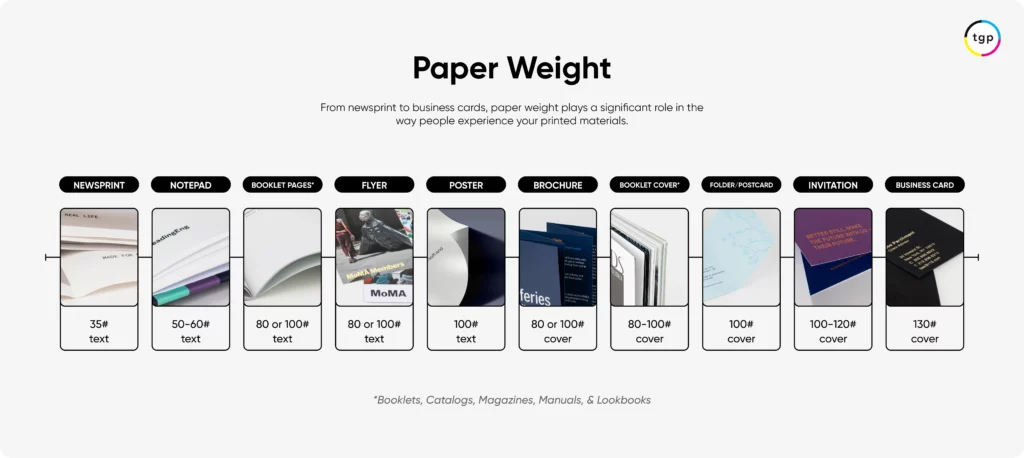

Paper Weight Guide For Printing

Now that you know how the commercial printing industry measures and categorizes paper weights, you’ll have a better idea of how to choose the right paper weight for your project.

Individual opinions on the right paper weight for specific publication types vary. If your project is a piece with a cover, like magazines and catalogs it’s often best to use heavier paper weight on the cover.

For example, in perfect-bound or saddle-stitched books, a heavy cover weight lends heft and substance, while a lighter paper is used for the printed text, for both affordability and readability.

While we’re happy to offer our suggestions for what types of paper may work well for your printing needs, you also are welcome to determine your own choice of paper from our wide range of in-house options.

Thinking about paper weight early on in the printing process is worthwhile. While you’re deciding your publication’s size, type, and how many pages are needed – paper weight is another consideration.

Popular Products For Your Next Project

- Book Printing13 standard sizes. 2 bind types.

- Magazine Printing13 standard sizes. 2 bind types.

- Newsprint Printing13 standard sizes. 2 bind types.

- Catalog PrintingSomething else here...

- Booklet Printing13 standard sizes. 2 bind types.

- Annual Report Printing13 standard sizes. 2 bind types.

What Paper Weight Should I Use?

Fortunately, there isn’t one right answer when it comes to paper weight. The type of publication you’re creating will help guide your paper weight, here are some common choices for different publications:

- 35# text: newsprint pieces like workbooks, magazines, and newspapers.

- 80# text: booklets, magazines, smaller catalogs, flyers

- 100# text: flyers, posters, inside pages of coffee table, art, or children’s books

- 80# cover: brochures, buckslips, and booklet covers

- 100# cover: brochures, buckslips, booklet covers, folders, postcards, and invitations.

- 130# cover: business cards, oversize perfect-bound books.

Considering your publication’s purpose, budget, and finishing will further help guide you in the right direction.

First, consider the purpose of your project. If your project is being mass-mailed, or marketed in large quantities, choosing a paper on the lighter end of what will work for you can cut down on weight-related mailing costs.

Then, think about your budget. Premium paper is simply more expensive, so balance your need for quality with your budget constraints.

Remember your target customer’s values. Premium grade is ideal for high-impact marketing materials, while standard grade is sufficient for everyday office needs. The heavier the paper, the more likely it is to be perceived as a high-quality product.

Finishing and formatting have an impact, too. If your design includes heavy ink coverage, a thicker stock may be needed to prevent ghosting. Cutting, folding, and stitching become progressively more difficult as paper weight increases, so think about how the paper will be used.

Still Unsure? Talk to a Printing Pro

Knowing the basics of paper weight will help you create a more authentic and more impressive printed product in the end. However, each project is unique, and we’re here to help you with any questions you have.

If you have any questions about paper weight or would like help deciding what paper best suits your printing project, please reach out to our experts at Thomas Group Printing. We’re a fourth-generation family-owned printing company in NYC and we’re always happy to lend our experience to our clients.

Before you get started on your printing project, create a free corporate account for perks like a dedicated account rep and free file checks, so your publication is produced fast and error-free.